Delaware Ducker

Duck it, lets go sailing!

Excellent under both oar and sail, large enough to carry a passenger but small enough to enjoy singlehanded, seaworthy enough for bay chop while staying low on weight and windage, just light enough to slide onto a cartop, the Delaware Ducker just seems to hit the sweet spot on so many compromises.

I adapted this hybrid glass/ply skin-on-frame “York” Ducker from plans available from Mystic Seaport. The overall build took about 160 hours. Cost completely finished was about $2000 for materials including the sail. My plan is to use it hard for a month and then post a design conclusion. The next step will be building a modified version based on what I learn from using the original. Little sailboats take a fair bit of money and time to put together so it remains to be seen how this will fit into the Cape Falcon lineup. For now I'm just enjoying the adventure.

Below are photos from the build, enjoy!

Excellent under both oar and sail, large enough to carry a passenger but small enough to enjoy singlehanded, seaworthy enough for bay chop while staying low on weight and windage, just light enough to slide onto a cartop, the Delaware Ducker just seems to hit the sweet spot on so many compromises.

I adapted this hybrid glass/ply skin-on-frame “York” Ducker from plans available from Mystic Seaport. The overall build took about 160 hours. Cost completely finished was about $2000 for materials including the sail. My plan is to use it hard for a month and then post a design conclusion. The next step will be building a modified version based on what I learn from using the original. Little sailboats take a fair bit of money and time to put together so it remains to be seen how this will fit into the Cape Falcon lineup. For now I'm just enjoying the adventure.

Below are photos from the build, enjoy!

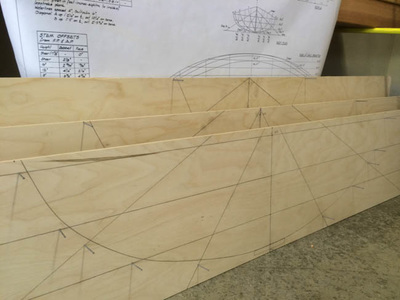

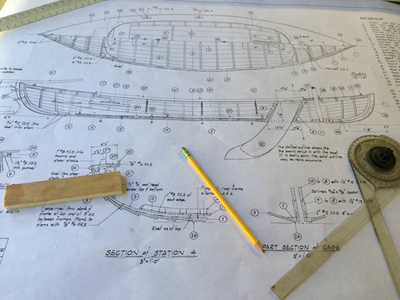

Day 1) Plotting the stations and building template for the stems. 6 hours.

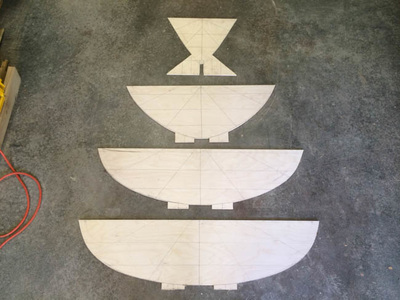

Day 2) Laying out the bottom board and laminating the stems. 6 hours.

Day 3) More layout, more forms, more jigs, attaching the bottom board to the stems, mock-up. 5 hours.

Day 4) Figure and cut compound angles, another mock up, cut pocket mortises, gudgeons arrive in mail. 5 hours.

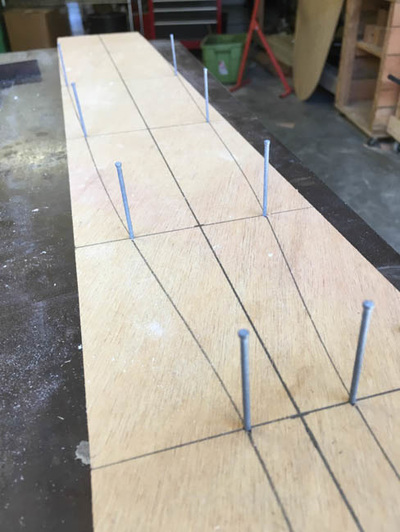

Day 5) Laying on the stringers, cutting bevels and tying in the ends. Cool shadows. 5 hours.

Day 6) Bending in the ribs and fastening them to the keel, stringers, and gunwale. 2 people, 5 hours.

Day 7) Fairing and nailing in the final stringers, making end blocks, planing down spruce, gluing up spars. 4 hours.

Day 8) Finding exact mast partner and dagger board locations, cutting the deck perimeter and cockpit. 5 hours.

Day 9) Reinforcing under the deck. Prefab dagger board trunk. 5 hours.

Day 10) Make, pilot, and countersink HDPE keel shoe. Make, glue, and seal mast step box. Join and seal underside of deck, glue on reinforced sections, seal and glue up daggerboard trunk. 6 hours.

Day 11) Making mistakes, fixing mistakes. Bedding the dagger trunk and mast step box in epoxy. Oiling the frame, fastening the deck, saturating the deck with epoxy. 2 people, 5 hours.

Day 12) Fiberglassing the deck, making oar pads, starting to shape the spars. 5 hours

Day 13) Cutting the blades off of old oars and gluing on new ones for the new shape. 4 hours.

Day 14) Building brass stanchions, bending/fastening the coaming, gluing on oar pads, fill coating the deck. 7 hours.

Day 15) More work on the spars, final fill coat on the deck. 5 hours.

Day 16) Completing the oars and the spars. 5 hours.

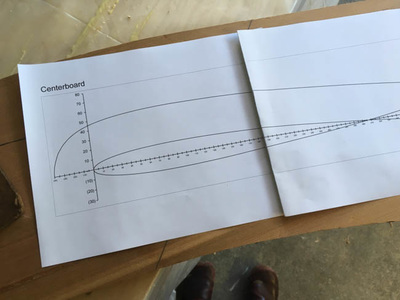

Day 17) Installing the aft seat, figuring out the dagger shape, gluing up the stock for the daggerboard. 5 hours.

Day 18) Cutting out the dagger and gluing up the rudder, laying out for foil section on the dagger. 5 hours.

Day 19) Shaping and glassing the rudder and daggerboard. 7 hours.

Day 20) RAIN COMING! ALL HANDS ON DECK. Skinning the boat, doing the final glass work on the daggerboard and rudder, coating the boat. 10 hours. (sorry for the bad pictures, very focused today)

Day 21) More work on the daggerboard and boom jaws, figuring out the unusual gudgeon and pintle arrangement.

4 hours.

4 hours.

Day 22) Polishing the rudder hardware, building the floorboards, starting work on the grub box, final sanding of the daggerboard. 5 hours.

Day 23) Building the grub box (seat box), beginning the interminable process of varnishing. 7 hours

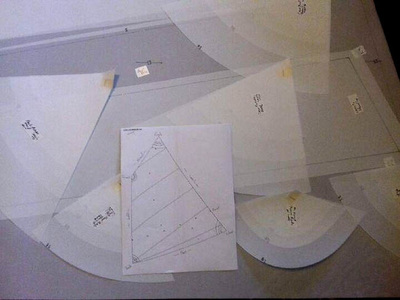

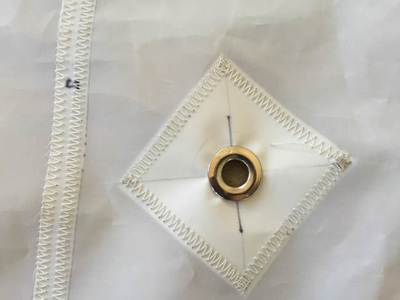

Day 24-26) A friend sews the sail. 12 hours

The Sailrite kit we bought was AMAZING, probably the best kit of any type I've ever seen. They had a pattern for the Ducker already. Panels are all precut and marked. Excellent instructions and a really high quality product.

The Sailrite kit we bought was AMAZING, probably the best kit of any type I've ever seen. They had a pattern for the Ducker already. Panels are all precut and marked. Excellent instructions and a really high quality product.

Day 24-26) Varnishing, and varnishing, and more varnishing. 6 hours.

Day 27) Screwing on the HDPE keel shoe, adding the drain plug, installing rudder hardware, making little open horn oarlocks out of a pair of round ones. Various hardware. 5 hours.

Day 28) Sewing on the oar leathers, rigging the sail, setting up the boat. 7 hours.

Day 29) Go sailing. As often as I can.